One year ago, Mondi, a global leader in packaging and paper opened its first in-house recyclability testing laboratory in Frantschach, Austria with the aim to test the recyclability of paper and paper-based packaging using non-paper components such as coatings. It is one of many examples of the pulp and paper industry’s total commitment to recyclability.

While paper packaging offers many sustainability benefits, it also has certain barrier functionality limitations for products like perishable food. To enhance its functionality, non-paper components such as barrier coatings may need to be added, which in turn can impact recyclability.

However, recyclability is an aspect of product sustainability with which the pulp and paper industry does not compromise. The shared goal of the sector is to reach a 90% recycling rate for fibre-based packaging by 2030. But research and development can be a lengthy process.

Speeding up the change

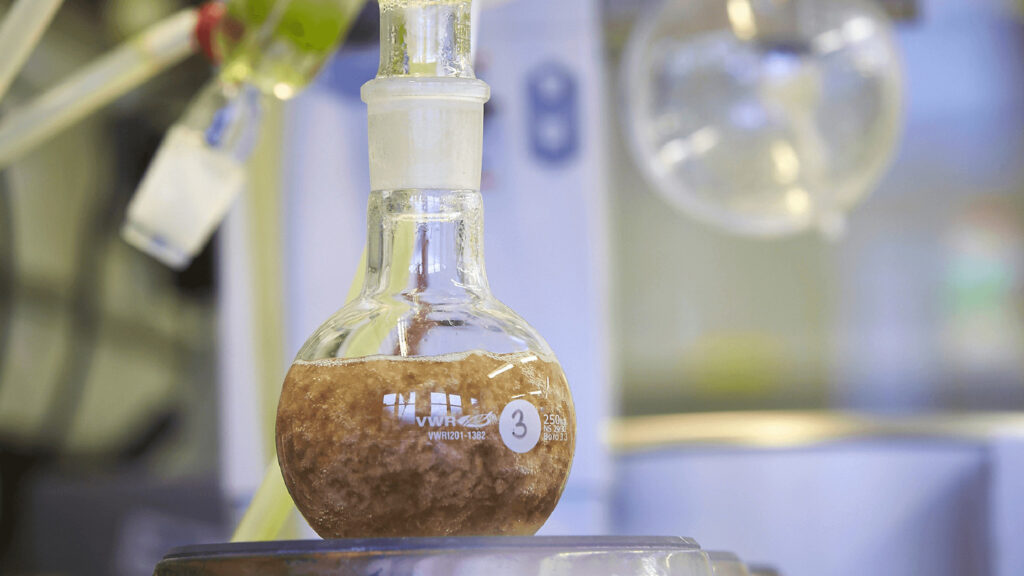

Conducting recycling tests in-house speeds up the process for developing sustainable packaging. The data collected at the laboratory can be used to improve existing products, provide reliable information about their environmental impact and determine whether the packaging can be efficiently recycled. Mondi also uses the results to determine how the design of new packaging can be improved as well as how best to improve the circularity of its material flows.

For this, the laboratory uses the Cepi harmonised European test method which enables it to verify recyclability of fibre-based packaging solutions. The laboratory works in a similar way to industrial recycling facilities, but on a smaller scale. Results generated provide concrete evidence that a given material can be recycled.

The ability to provide customers with information on the recyclability of our products will be a key enabler in Mondi’s efforts to develop more sustainable solutions and enhance the value proposition to customers. Currently, 78% of Mondi’s group wide portfolio is already either reusable, recyclable or compostable. This recycling lab enables Mondi to move closer to its MAP2030 goals of making 100% of its products fulfil these requirements by 2025.

Plastics too

Apart from and paper-based materials, research at Mondi is also underway to increase the recyclability of plastics. Mondi invested €5 million in a new R&D centre in Steinfeld, in Germany. When completed, the new facility will include pilot lines for both plastic- and paper based solutions as well as an analytical laboratory and a customer experience centre. This will enable Mondi to work with our customers to accelerate the delivery of scalable solutions.

In 2022, Mondi was one of 80 global businesses, financial institutions and non-governmental organisations, which endorsed a common vision for an effective and ambitious UN Global Treaty to End Plastic Pollution.