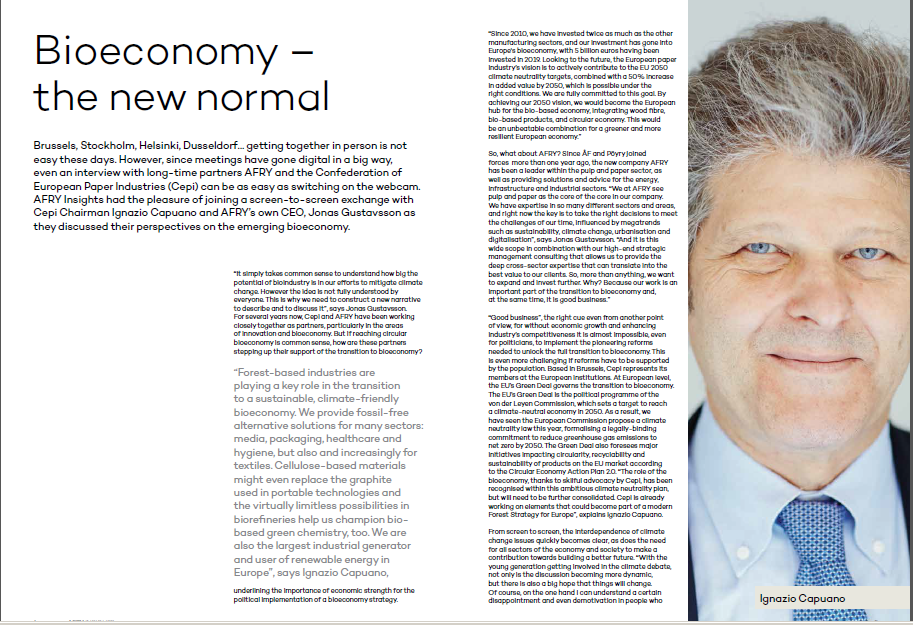

“Bioeconomy – the new normal”: Cepi Chairman Ignazio Capuano for AFRY Magazine

For the first issue of AFRY Insights Bioindustry magazine, Cepi Chairman Ignazio Capuano, and AFRY’s CEO, Jonas Gustavsson, discuss their perspectives on the emerging bioeconomy.

“Forest-based industries are playing a key role in the transition to a sustainable, climate-friendly bioeconomy. We provide fossil-free alternative solutions for many sectors: media, packaging, healthcare and hygiene, but also and increasingly for textiles. Cellulose-based materials might even replace teh graphite used in portable technologies and the virtually limitless possibilities in biorefineries help us champion biobased green chemistry, too. We are also the largest industrial generator and user of renewable energy in Europe” Ignazio Capuano.

Read the full interview here.

#ForestBiodiversity: A new platform to show how sustainable forest management supports biodiversity preservation

“Listen to EU forest stewards, understand their actions on the ground, learn from their experience, and go beyond the clichés!” In a few words, this is the message of the new awareness campaign #ForestBiodiversity launched today in Brussels by 6 associations representing the European Forest-based Sector.

As the debate around the biodiversity and forest strategies has never been so high on the agenda, this joint initiative gives the floor to European forest owners and managers through a series of videos available on the dedicated platform forestbiodiversity.eu. The interviews concretely show that behind the concept of sustainable forest management, special attention is given to biodiversity preservation and climate adaptation- two essential objectives for the forest owners and managers when managing forests.

Sustainable Forest Management provides a balance between biodiversity preservation, climate protection and socio-economic viability that local players, forest owners and managers, ensure on a daily basis. This multidimensionality in forest management is sometimes misunderstood.

Well managed forests have the capacity to remain a home for biodiversity in times of natural disturbances and changing climate. Well managed forests have the capacity to foster a greater amount of CO2 and increase carbon storage in forests and wood products as well as substituting for fossil-based materials and energy. Well managed forests have the capacity to be the first link in a value chain that provides nearly 4 million green European jobs while also offering preserved spaces for all.

Only resilient and healthy forests can continue to deliver multiple ecosystem services, including biodiversity preservation. Conservation and enhancement of biodiversity are at the heart of Sustainable Forest Management.

Download here.

14TH CENTURY European papermakers continue the innovation

The export of the technique of papermaking to Europe, especially to Italy, has been well documented. From the 13th century onwards, papermakers at two early Italian centres, Fabriano and Amalfi, tried to improve upon the Arabian technique.

The Italian papermakers introduced a series of improvements to the papermaking process:

- the use of water to power the machinery

- the stamping mill was used to produce pulp more efficiently (derived from the machines used in textile handicrafts)

- the mould made of wire mesh (as a result of progress in wire production), which triggered

- the introduction of couching on felt

- the paper press with slides for feeding in the material, which quickens

- the drying process the drying of the sheets of paper on ropes

- the introduction of dip sizing – sizing is when a substance is applied to paper to change its surface properties, e.g. to improve strength or reduce absorbency of water

In the course of the rapid expansion of trade in the late Middle Ages, paper merchants were dealing with a commodity that was growing in importance for European public and intellectual life.

The first documented papermaking on German soil was in 1390 when the Nuremberg councillor Ulmann Stromer commissioned a paper mill.

His mill was initially designed with 2 waterwheels, 18 stamping hammers and 12 workers using one or two vats.

16TH CENTURY Literature and literacy supported by paper mills’ increasing productivity

The advantages of mill-based papermaking spread throughout Europe in the 15th and 16th centuries.

In Germany, by the end of the 16th century there were 190 mills.

Work at the paper mill was typically carried out by a four man team: the vatman took the pulp from a vat and made the sheet using a mould; the couch squirt, who worked in harmony with the vatman, placed the sheet on absorbent felt; the layman, who drew off the still moist sheets from the felt after pressing; and the apprentice, who had to feed material into the vat and maintained the heating of the vat.

Up to nine reams (4,500 sheets) of paper could be made in the course of a working day of around 13 hours.

17&18TH CENTURIES Papermaking technology improves – demand for paper increases

Technical progress continued throughout the 17th Century. The invention of the ‘Hollander beater’ confirmed the Dutch as being at the forefront of papermaking technology. It was a much more efficient way to make pulp compared with the stamping mill, which it began to replace, dividing papermakers into traditional versus modern camps.

Meanwhile, improvements in the printing process, namely the introduction of movable type, greatly increased demand for paper. It led to a serious shortage of raw materials and to regulations governing the trade in rags, the primary raw material for making paper.

The 18th century saw the establishment of larger-scale operations. Such ‘manufactories’ were dependent on skilled papermakers who were organised into craft groups. The search for innovations to step up production and to have as many of the jobs done by machine as possible (partly to overcome the constraining rules of the papermakers) culminated in the design and construction of new papermaking machines.

The initial model built, by J.N.L. Robert in 1798, was the first flat-screen papermaking machine. The design was further developed in England, mostly by Donking and the Fourdrinier brothers. Additionally, the French chemist Claude-Louis Bertholett invented the chemical bleaching of pulp in 1785. The French Revolutionaries were probably the first to use really white paper.

18th edition of European Paper Week opens with a renewed focus on innovation, investment and future skills

CEPI, the organisation representing the European paper industry has opened its 18th edition of its annual event European Paper Week welcoming nearly 350 movers and shakers from the across the European paper industry and the four corners of the globe.

This year’s programme set the tone for its positive agenda ahead as we enter 2017. At this year’s event attendees will be provided with the opportunity to meet CEPI’s new Director General, Sylvain Lhôte as well as its Chairman, Peter Oswald (CEO Mondi Group, Europe & International Division).

The highlight of this year’s event, the high-level session includes notable speakers such as Gideon Rachman, chief foreign affairs commentator of the Financial Times, Lucrezia Reichlin of the London Business School, Signe Ratso, Director, DG TRADE, the EIB as well as Moody’s. The discussion will reflect on global economic trends and the investment implications for the European paper industry.

As an indication of the strides forward industry has made on the innovation agenda this year’s event will open with ten young researchers showcasing their industry-changing ideas. Three of them will be in line for the prestigious global Blue Sky Innovation Award to be launched for the first time in 2017.

This will be complemented on Wednesday by a session dedicated to the 2017 prospects for the energy market and a joint session with our partners from RISI on the global market outlook ahead. During this discussion we will be joined by Innventia who will present their groundbreaking”Cellulose-Based Society” report.

On top of this together with our trade union partners Industriall we will discuss the need for policymakers to tip the balance in favour of supporting the skills and competences necessary for the bioeconomy transition. Most significantly we will address the outcome of European Commission study demonstrating the financial burden of EU regulations and the detrimental impact on industry’s ability to reinvest and to ensure industrial transformation happens in Europe.

Finally our new Director General will launch the discussion on the way forward for our 2050 Roadmap outlining industry’s vision to move forward on the path towards a low-carbon, circular bioeconomy by 2050 in Europe, for Europe. This roadmap will be immediately open for contributions from stakeholders.

For more information please contact Ben Kennard at or by phone (+32) 487 3921 82

Note to editor

CEPI aisbl – The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing the industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus

Norway) CEPI represents some 505 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 920 paper mills. Together they represent 23% of world production.

Website: http://www.cepi.org/

19 June 2020, 10-12h CEST Public Webinar: Climate effects of the forest-based sector in the European Union

Read the press release.

Please read the study executive summary here.

Full version of the study.

Watch the webinar.

Download the presentation.

10.00 Opening and presentation of the study

Jori Ringman, Director General, Confederation of European Paper Industries (Cepi)

10.15 Interpretation of key findings

Dr Peter Holmgren, Forestry specialist and the former Director General of the Center for International Forestry Research, study author

10:35 Comments on link between sink, sequestration and substitution

Fanny-Pomme Langue, Secretary General, Confederation of European Forest Owners (CEPF)

10:40 Comments on the contribution of wood and carbon storage in wood products

Patrizio Antonicoli, Secretary General, European Confederation of Woodworking industries (CEI-Bois)

10.45 Policy perspective on the climate effect of forest-based products

Alfonso Gutierrez Teira Head of Sector for Forestry, Unit D.4. – Environment, climate change, forestry & bioeconomy, DG AGRI, European Commission

11:15 Q&A

12:00 End of the webinar

19&20TH CENTURY Full-scale industrialisation – innovation and specification lead to new paper grades and paper uses

Gradually, the paper production process became fully automated: from the preparatory and pulp production stages through to the papermaking, use of fillers and finishing (including the headbox, wire section, pressing, drying, reeling, smoothing and packaging).

The paper industry developed appropriate industrial plants (groundwood and chemical pulp mills) in order to produce wood based paper on an industrial scale and to meet the demand for this increasingly valued substitute for rags which was set to become the dominant raw material for papermaking.

The second half of the 19th century was marked by the enlargement of the web width, an increase in working speeds due to improvements to various machine parts. Machines were designed specifically for particular paper and corrugated board products, (for example, the Yankee cylinder for tissue paper production). The web working width grew from 85 cm (1830) to 770 cm (1930), while production speeds rose from 5 m/min. (1820) to over 500 m/min. (1930).

In the past 50 years the rate of innovation in papermaking has increased rapidly. New materials have been developed (using thermo-mechanical pulps, recovered paper and new fillers). New sheet forming options and neutral sizing have been accompanied by a greater awareness and focus on environmental impacts.

New products and solutions are constantly being developed to meet the most complex of challenges. And it’s not just the finished products which have changed.

The continuous evolution of paper technology and production processes has increased speed, productivity and enhanced production quality whilst becoming increasingly responsive to environmental concerns. New technologies are in place to make paper lighter, reduce energy consumption and to generate biofuels.

Innovation has also led to greater specialisation by paper makers, for example in the development of new paper grades such as LWC – lightweight coated paper (mainly used in magazines, flyers and inserts such as coupons); and some paper groups have acquired their own raw material supply and trading organisations.

19TH CENTURY Emergence of wood based paper and increased mechanisation

The systematic search for substitute raw materials with which to produce paper in Europe proved difficult. In the early 18th century straw was used as a raw material but it failed to make headway due to quality concerns.

However, in 1843, a solution was at hand, Saxon Friedrich Gottlob Keller invented a wood-grinding machine which produced groundwood pulp suitable for papermaking. This milestone was soonfollowed by an alternative way to turn wood into paper: chemical pulp was first patented in 1854 by Hugh Burgers and Charles Watt.

Following the invention of the first papermaking machine by J.N.L. Robert in 1798, other machines soon appeared on the market, such as Dickinson’s cylinder machine. The machines could continuously fill wire moulds and couch the sheets of paper on felt.

Flat screen and cylinder machines, which were first seen in the 19th century, were continually improved and extended to include a dryer section. This soon led to a considerable widening of the paper web and to an increase in production speeds.

2013 ICFPA Sustainability Progress Report

2015 ICFPA Sustainability Progress Report

The International Council of Forest and Paper Associations (ICFPA) has launched its 2015 Sustainability Progress Report, showing improvements on a range of sustainability indicators and focusing on the industry’s contributions toward a green economy.

The full report is also available on the ICFPA website at http://www.icfpa.org/uploads/Modules/Publications/2015-icfpa-sustainability-progress-report.pdf.

Read the press release on the topic here.

The global sustainability performance of the forest product industry is improving, with all aggregate indicators for reporting associations showing progress:

• Greenhouse gas emissions intensity was reduced by 17% between 2005 and 2013.

• The share of bio-energy in the industry’s fuel mix increased by 8 percentage points, to 61%, since 2005.

• The number of hectares certified to a third-party sustainable forest management certification system increased by 41 percentage points, to 52% of wood supply, since 2000.

• The global paper recycling rate increased by 11 percentage points, to 58%, between 2001 and 2013.

• Onsite energy intensity was reduced by 4.3% between 2005 and 2013.

• Sulfur dioxide (SO2) emissions decreased by 40% between 2005 and 2013.

• Employees’ recordable incident rate decreased by 9% between 2007 and 2013.

In addition to reporting on performance, the Sustainability Progress Report illustrates how the forest and paper industry is supporting a green economy through resource efficiency, carbon sequestration, innovative technologies, bio-based products, and benefiting communities. Contributing to the 2015 report are forest and paper industry associations from Australia, Brazil, Canada, Chile, China, Europe, Japan, New Zealand, South Africa, and the United States.

For more information about the sustainability of the global forest and paper industry, visit icfpa.org.

2030 Industry Manifesto

In 2011, as a leading industry Cepi published a 2050 Roadmap to a low-carbon bio-economy (here). Cepi is now releasing the 2030 Manifesto that takes into account the new adopted targets in the framework of the EU Green Deal.

“The Pulp and Paper sector is in a key position to support

the EU in becoming fit for 2050. Our sector has several

potentials to substantially and sustainably reduce greenhouse

gas emissions. In order to achieve these aspirations,

the availability of political support will be critical.”

21 March – International Day of Forests

European pulp and paper industry takes care of the forest

“The paper industry destroys forests”:a common misconception put forward by environmentalists all around the globe. What they don’t realise is that the European paper industry…

– contributes to keep up forests.

– practices sustainable forest management.

– is not responsible for the depletion of tropical forests.

From all the wood extracted around the world’s forests, 53% is used for energy production, 28% is used by sawmills and only around 11% is used directly by the paper industry(1). The paper industry depends on wood and needs thriving forests. It is very much in our interest that wood is used sustainably and will remain available as a raw material to future generations.

From a tree the branches cut to maintain a healthy forest are used for paper making. Residues from saw mills such as wood chips, are also used as raw material for paper. Over the years, thinning operations weed out the weaker trees, but there is still a net gain. The Food and Agriculture Organization (FAO) calculates that the annual increase of forest cover in EU 27 member countries is app. 503 000 ha/yr. This corresponds to the size of 3403 football (soccer) fields per day and an area almost twice as large as Luxembourg every year(2).

Deforestation is generally occurring in the southern hemisphere and is mainly due to unsustainable agricultural practices and fuel requirements. The European paper industry supports sustainable forest management as well as certification. A sustainable forest management strategy aimed at maintaining or increasing forest growth, while producing an annual sustained yield of wood, will generate the largest carbon storage benefit(3). We support certification as a way of documenting sustainable forest management. Certificates based on defined criteria issued by independent auditors make this verifiable for customers and consumers(4). Half of Europe’s forests and 92.2% of forests owned by paper companies are certified(5).

In Europe, the paper industry signed up for a Legal Logging Code of Conduct(6) in 2005 firmly condemning illegal logging and related corruption and criminal activities. Our commitment to responsible sourcing is clear and beyond any reasonable doubt.

More forest related news in the European paper industry at http://www.cepi.org/topics/forest

Or visit paperonline.org for more myth busters at http://www.paperonline.org/myths-and-realities

Information about the International Day of Forests: http://www.fao.org/forestry/international-day-of-forests/en/

1. FAO Statistics 2007

2. FAO Statistics 2010

3. 4th Assessment of the UN intergovernmental Panel on Climate Change (IPCC)

4. To learn more about certification, please visit www.fsc.org and www.pefc.org

5. CEPI Sustainability Report 2011

6. Legal Logging Code of Conduct for the Paper Industry

21TH CENTURY & BEYOND…

Paper is an amazing product: it is renewable, clean and incredibly versatile. It continuously offers new possibilities, applications and end-uses.

Paper can be impregnated, enamelled, crêped, waterproofed, waxed, glazed, sensitised, bent, folded, twisted, crumpled, cut, torn, dissolved, moulded and embossed. Who knows to what uses it will be put in the future?

Today, intelligent paper used in packaging allows us to see clearly if products are past their sell-by date by changing colour, printed electronic circuits can be used instead of traditional heavy circuit boards, scratch and sniff books bring learning to life, radio identification tags allow products to be traced at every stage, and even batteries can be made from paper.

What is sure is that the European pulp and paper industry will continue to change and adapt to new market conditions, responding to consumer requirements, and moving closer to its vision of integrated sustainability and competitiveness.

Paper mills have improved enormously from an environmental point of view (waste water, emissions, etc.) as well as from an efficiency point of view (see Environment section).

3.5 million jobs at risk if EU grants Market Economy Status to China, finds new report

A landmark study by the Economic Policy Institute (EPI) released last week reveals that if the EU grants Market Economy Status (MES) to China, the EU could lose 3.5 million jobs and 2% of GDP. Read AEGIS Europe press release here.

CEPI is a member of the AEGIS alliance. Follow AEGIS on Twitter @AEGISeurope

4evergreen launch event – Virginijus Sinkevičius, EU Commissioner for Environment

“This alliance is clearly in step with our thinking and with our objectives for a circular low-carbon future. A future where sustainability goes hand in hand with innovation and creates exciting business opportunities“

Welcome and video address by Virginijus Sinkevičius, EU Commissioner for Environment, at the official 4evergreen launch event on 25 Nov 2020. Watch the full message:

5th European Paper Recycling Awards call for candidates is open!

The European Recovered Paper Council (ERPC) launched a call for candidates for the 2015 European Paper Recycling Awards. The awards will identify projects, initiatives and campaigns that contribute to Europe’s sustainability through activities supporting paper recycling. Winners will be announced at the official awards ceremony taking place at the European Parliament on 14 October.

Now in their fifth edition, the awards are open to all entities based in Europe, including schools and universities, NGOs, national and regional authorities, companies and associations.

Read the press release here.

To apply, please visit the ERPC website at www.paperforrecycling.eu.

A Checklist for EU and Climate Policies

The document is available here.

A joint call for an updated and stronger EU Forest Strategy

Acknowledging the report from the European Commission on progress in the implementation of the Forest Strategy the undersigned organizations, representing forest owners, managers, contractors and the forest-based industry, call on the European Commission, Parliament and Council to update the EU Forest Strategy with an aim to strengthen its role as a key reference for sustainable forest management. An update of the EU Forest Strategy is essential to ensure that the development of forest-related EU policies in the coming decades is better coordinated and more coherent.

Since the EU Forest Strategy was adopted in 2013, the EU policy framework and the EU policies affecting forests have strongly evolved. It is now more broadly recognized that forests and the forest sector play a crucial role in addressing major challenges in line with the United Nation’s Sustainable Development Goals and the climate change mitigation goals of the Paris Agreement.

In this context, special care must be taken to recognize the role of Sustainable Forest Management (SFM) to ensure forest ecosystem’s health and vitality and the delivery of multiple advantages to society and the bioeconomy.

However, forests and the forest-based sector are now increasingly expected to deliver on horizontal and sectoral EU policies addressing forests. These include:

– The 2050 Climate Change Mitigation Strategy that aims to maximize the potential of carbon storage in forests while providing raw materials for renewable products used to substitute for non-renewable materials as well as for energy.

– The land use and forestry regulation for 2021-2030 which commits Member States, for the first time in EU law, to compensate land use and forestry sector emissions by CO2 removals within the sector.

– The European Commission proposal for a taxonomy of sustainable investments which recognizes the central importance of sustainable forest management for protecting ecosystems.

– The EU Renewable Energy Directive that sets out bioenergy sustainability criteria related to forest management and GHG emissions savings.

– The updated EU Bioeconomy Strategy that encourages the transition to a more bio-based circular economy, bringing new opportunities for jobs and growth to rural areas.

– The future CAP which is the main instrument at EU level to finance measures that support SFM and investments for enhancing the sustainability and competitiveness of the forestry sector.

– The EU Biodiversity Strategy which aims to halt the loss of biodiversity and ecosystem services in the EU and which the Commission has recently started to evaluate.

The consequences of these policies and strategies on forests and their sustainable management still need to be ascertained. Therefore, their implementation during the period 2020-2030 and beyond must be closely monitored from a forestry perspective. In this context, the EU Forest Strategy can and should provide a consistent basis on which to strengthen and further establish effective links between forests and the forest-based sector and any relevant EU policies.

Beyond consistency throughout its legislation and policies, the EU also needs an efficient tool to address forest and forest-related issues on the pan-European and international agendas. Member States and their pan-European partners in Forest Europe are determined to continue discussions on a legally binding agreement on forests. At global level, a well-prepared and coordinated input is needed to the UN Strategic Plan for Forests 2030 and the Global Forest Goals. A robust EU Forest Strategy is the appropriate instrument to ensure consistent input to these processes, thereby making the EU a strong and committed partner.

Over the last years the Strategy has undoubtedly played a positive role in this context.

However, more needs to be done both at EU and national level to ensure even better policy consistency and coherence in the future. The roles of the Standing Forestry Committee and also of the Civil Dialogue Group on Forestry and Cork are very important in this context.

While the progress report highlights the importance of continued implementation of the strategy, it refrains from concrete recommendations for the post-2020 period. Therefore the undersigned organizations call on the European Commission, Parliament and Council to propose an updated and stronger EU Forest Strategy, before the end of 2019, which encompasses recent and upcoming EU policies and is adequately resourced at the appropriate levels of the European institutions.

CEETTAR – European Organisation of Agricultural, Rural and Forestry Contractors

CEI-BOIS – European Confederation of the Woodworking Industries

CEPF – Confederation of European Forests Owners

CEPI – Confederation of European Paper Industries

COPA COGECA – European Farmers and European Agri-cooperatives

ELO – European Landowners’ Organization

EUSTAFOR – European State Forest Association

UEF – Union of European Foresters USSE – L’Union des Sylviculteurs du Sud de l’Europe

A long-term strategy for Europe’s industrial future: from words to action

The Joint Paper presents concrete industrial policy proposals in seven priority fields; business-friendly policy environment, sustainability at business core, upgraded skills and training, enhanced research and innovation, investment and improved access to finance, reinforcement of the European Single Market and strengthened trade and international market access.

The 149 industry organisations behind Industry4Europe stand united in their repeated calls for an ambitious and long-term EU industrial strategy that must help Europe remain a hub for a leading, smart, innovative and sustainable industry, that provides quality jobs and benefits all Europeans and future generations.

“Bioeconomy – the new normal”: Cepi Chairman Ignazio Capuano for AFRY Magazine

For the first issue of AFRY Insights Bioindustry magazine, Cepi Chairman Ignazio Capuano, and AFRY’s CEO, Jonas Gustavsson, discuss their perspectives on the emerging bioeconomy.

“Forest-based industries are playing a key role in the transition to a sustainable, climate-friendly bioeconomy. We provide fossil-free alternative solutions for many sectors: media, packaging, healthcare and hygiene, but also and increasingly for textiles. Cellulose-based materials might even replace teh graphite used in portable technologies and the virtually limitless possibilities in biorefineries help us champion biobased green chemistry, too. We are also the largest industrial generator and user of renewable energy in Europe” Ignazio Capuano.

Read the full interview here.

#ForestBiodiversity: A new platform to show how sustainable forest management supports biodiversity preservation

“Listen to EU forest stewards, understand their actions on the ground, learn from their experience, and go beyond the clichés!” In a few words, this is the message of the new awareness campaign #ForestBiodiversity launched today in Brussels by 6 associations representing the European Forest-based Sector.

As the debate around the biodiversity and forest strategies has never been so high on the agenda, this joint initiative gives the floor to European forest owners and managers through a series of videos available on the dedicated platform forestbiodiversity.eu. The interviews concretely show that behind the concept of sustainable forest management, special attention is given to biodiversity preservation and climate adaptation- two essential objectives for the forest owners and managers when managing forests.

Sustainable Forest Management provides a balance between biodiversity preservation, climate protection and socio-economic viability that local players, forest owners and managers, ensure on a daily basis. This multidimensionality in forest management is sometimes misunderstood.

Well managed forests have the capacity to remain a home for biodiversity in times of natural disturbances and changing climate. Well managed forests have the capacity to foster a greater amount of CO2 and increase carbon storage in forests and wood products as well as substituting for fossil-based materials and energy. Well managed forests have the capacity to be the first link in a value chain that provides nearly 4 million green European jobs while also offering preserved spaces for all.

Only resilient and healthy forests can continue to deliver multiple ecosystem services, including biodiversity preservation. Conservation and enhancement of biodiversity are at the heart of Sustainable Forest Management.

Download here.

14TH CENTURY European papermakers continue the innovation

The export of the technique of papermaking to Europe, especially to Italy, has been well documented. From the 13th century onwards, papermakers at two early Italian centres, Fabriano and Amalfi, tried to improve upon the Arabian technique.

The Italian papermakers introduced a series of improvements to the papermaking process:

- the use of water to power the machinery

- the stamping mill was used to produce pulp more efficiently (derived from the machines used in textile handicrafts)

- the mould made of wire mesh (as a result of progress in wire production), which triggered

- the introduction of couching on felt

- the paper press with slides for feeding in the material, which quickens

- the drying process the drying of the sheets of paper on ropes

- the introduction of dip sizing – sizing is when a substance is applied to paper to change its surface properties, e.g. to improve strength or reduce absorbency of water

In the course of the rapid expansion of trade in the late Middle Ages, paper merchants were dealing with a commodity that was growing in importance for European public and intellectual life.

The first documented papermaking on German soil was in 1390 when the Nuremberg councillor Ulmann Stromer commissioned a paper mill.

His mill was initially designed with 2 waterwheels, 18 stamping hammers and 12 workers using one or two vats.

16TH CENTURY Literature and literacy supported by paper mills’ increasing productivity

The advantages of mill-based papermaking spread throughout Europe in the 15th and 16th centuries.

In Germany, by the end of the 16th century there were 190 mills.

Work at the paper mill was typically carried out by a four man team: the vatman took the pulp from a vat and made the sheet using a mould; the couch squirt, who worked in harmony with the vatman, placed the sheet on absorbent felt; the layman, who drew off the still moist sheets from the felt after pressing; and the apprentice, who had to feed material into the vat and maintained the heating of the vat.

Up to nine reams (4,500 sheets) of paper could be made in the course of a working day of around 13 hours.

17&18TH CENTURIES Papermaking technology improves – demand for paper increases

Technical progress continued throughout the 17th Century. The invention of the ‘Hollander beater’ confirmed the Dutch as being at the forefront of papermaking technology. It was a much more efficient way to make pulp compared with the stamping mill, which it began to replace, dividing papermakers into traditional versus modern camps.

Meanwhile, improvements in the printing process, namely the introduction of movable type, greatly increased demand for paper. It led to a serious shortage of raw materials and to regulations governing the trade in rags, the primary raw material for making paper.

The 18th century saw the establishment of larger-scale operations. Such ‘manufactories’ were dependent on skilled papermakers who were organised into craft groups. The search for innovations to step up production and to have as many of the jobs done by machine as possible (partly to overcome the constraining rules of the papermakers) culminated in the design and construction of new papermaking machines.

The initial model built, by J.N.L. Robert in 1798, was the first flat-screen papermaking machine. The design was further developed in England, mostly by Donking and the Fourdrinier brothers. Additionally, the French chemist Claude-Louis Bertholett invented the chemical bleaching of pulp in 1785. The French Revolutionaries were probably the first to use really white paper.

18th edition of European Paper Week opens with a renewed focus on innovation, investment and future skills

CEPI, the organisation representing the European paper industry has opened its 18th edition of its annual event European Paper Week welcoming nearly 350 movers and shakers from the across the European paper industry and the four corners of the globe.

This year’s programme set the tone for its positive agenda ahead as we enter 2017. At this year’s event attendees will be provided with the opportunity to meet CEPI’s new Director General, Sylvain Lhôte as well as its Chairman, Peter Oswald (CEO Mondi Group, Europe & International Division).

The highlight of this year’s event, the high-level session includes notable speakers such as Gideon Rachman, chief foreign affairs commentator of the Financial Times, Lucrezia Reichlin of the London Business School, Signe Ratso, Director, DG TRADE, the EIB as well as Moody’s. The discussion will reflect on global economic trends and the investment implications for the European paper industry.

As an indication of the strides forward industry has made on the innovation agenda this year’s event will open with ten young researchers showcasing their industry-changing ideas. Three of them will be in line for the prestigious global Blue Sky Innovation Award to be launched for the first time in 2017.

This will be complemented on Wednesday by a session dedicated to the 2017 prospects for the energy market and a joint session with our partners from RISI on the global market outlook ahead. During this discussion we will be joined by Innventia who will present their groundbreaking”Cellulose-Based Society” report.

On top of this together with our trade union partners Industriall we will discuss the need for policymakers to tip the balance in favour of supporting the skills and competences necessary for the bioeconomy transition. Most significantly we will address the outcome of European Commission study demonstrating the financial burden of EU regulations and the detrimental impact on industry’s ability to reinvest and to ensure industrial transformation happens in Europe.

Finally our new Director General will launch the discussion on the way forward for our 2050 Roadmap outlining industry’s vision to move forward on the path towards a low-carbon, circular bioeconomy by 2050 in Europe, for Europe. This roadmap will be immediately open for contributions from stakeholders.

For more information please contact Ben Kennard at or by phone (+32) 487 3921 82

Note to editor

CEPI aisbl – The Confederation of European Paper Industries

The Confederation of European Paper Industries (CEPI) is a Brussels-based non-profit organisation regrouping the European pulp and paper industry and championing the industry’s achievements and the benefits of its products. Through its 18 member countries (17 European Union members plus

Norway) CEPI represents some 505 pulp, paper and board producing companies across Europe, ranging from small and medium sized companies to multi-nationals, and 920 paper mills. Together they represent 23% of world production.

Website: http://www.cepi.org/

19 June 2020, 10-12h CEST Public Webinar: Climate effects of the forest-based sector in the European Union

Read the press release.

Please read the study executive summary here.

Full version of the study.

Watch the webinar.

Download the presentation.

10.00 Opening and presentation of the study

Jori Ringman, Director General, Confederation of European Paper Industries (Cepi)

10.15 Interpretation of key findings

Dr Peter Holmgren, Forestry specialist and the former Director General of the Center for International Forestry Research, study author

10:35 Comments on link between sink, sequestration and substitution

Fanny-Pomme Langue, Secretary General, Confederation of European Forest Owners (CEPF)

10:40 Comments on the contribution of wood and carbon storage in wood products

Patrizio Antonicoli, Secretary General, European Confederation of Woodworking industries (CEI-Bois)

10.45 Policy perspective on the climate effect of forest-based products

Alfonso Gutierrez Teira Head of Sector for Forestry, Unit D.4. – Environment, climate change, forestry & bioeconomy, DG AGRI, European Commission

11:15 Q&A

12:00 End of the webinar

19&20TH CENTURY Full-scale industrialisation – innovation and specification lead to new paper grades and paper uses

Gradually, the paper production process became fully automated: from the preparatory and pulp production stages through to the papermaking, use of fillers and finishing (including the headbox, wire section, pressing, drying, reeling, smoothing and packaging).

The paper industry developed appropriate industrial plants (groundwood and chemical pulp mills) in order to produce wood based paper on an industrial scale and to meet the demand for this increasingly valued substitute for rags which was set to become the dominant raw material for papermaking.

The second half of the 19th century was marked by the enlargement of the web width, an increase in working speeds due to improvements to various machine parts. Machines were designed specifically for particular paper and corrugated board products, (for example, the Yankee cylinder for tissue paper production). The web working width grew from 85 cm (1830) to 770 cm (1930), while production speeds rose from 5 m/min. (1820) to over 500 m/min. (1930).

In the past 50 years the rate of innovation in papermaking has increased rapidly. New materials have been developed (using thermo-mechanical pulps, recovered paper and new fillers). New sheet forming options and neutral sizing have been accompanied by a greater awareness and focus on environmental impacts.

New products and solutions are constantly being developed to meet the most complex of challenges. And it’s not just the finished products which have changed.

The continuous evolution of paper technology and production processes has increased speed, productivity and enhanced production quality whilst becoming increasingly responsive to environmental concerns. New technologies are in place to make paper lighter, reduce energy consumption and to generate biofuels.

Innovation has also led to greater specialisation by paper makers, for example in the development of new paper grades such as LWC – lightweight coated paper (mainly used in magazines, flyers and inserts such as coupons); and some paper groups have acquired their own raw material supply and trading organisations.

19TH CENTURY Emergence of wood based paper and increased mechanisation

The systematic search for substitute raw materials with which to produce paper in Europe proved difficult. In the early 18th century straw was used as a raw material but it failed to make headway due to quality concerns.

However, in 1843, a solution was at hand, Saxon Friedrich Gottlob Keller invented a wood-grinding machine which produced groundwood pulp suitable for papermaking. This milestone was soonfollowed by an alternative way to turn wood into paper: chemical pulp was first patented in 1854 by Hugh Burgers and Charles Watt.

Following the invention of the first papermaking machine by J.N.L. Robert in 1798, other machines soon appeared on the market, such as Dickinson’s cylinder machine. The machines could continuously fill wire moulds and couch the sheets of paper on felt.

Flat screen and cylinder machines, which were first seen in the 19th century, were continually improved and extended to include a dryer section. This soon led to a considerable widening of the paper web and to an increase in production speeds.

2013 ICFPA Sustainability Progress Report

2015 ICFPA Sustainability Progress Report

The International Council of Forest and Paper Associations (ICFPA) has launched its 2015 Sustainability Progress Report, showing improvements on a range of sustainability indicators and focusing on the industry’s contributions toward a green economy.

The full report is also available on the ICFPA website at http://www.icfpa.org/uploads/Modules/Publications/2015-icfpa-sustainability-progress-report.pdf.

Read the press release on the topic here.

The global sustainability performance of the forest product industry is improving, with all aggregate indicators for reporting associations showing progress:

• Greenhouse gas emissions intensity was reduced by 17% between 2005 and 2013.

• The share of bio-energy in the industry’s fuel mix increased by 8 percentage points, to 61%, since 2005.

• The number of hectares certified to a third-party sustainable forest management certification system increased by 41 percentage points, to 52% of wood supply, since 2000.

• The global paper recycling rate increased by 11 percentage points, to 58%, between 2001 and 2013.

• Onsite energy intensity was reduced by 4.3% between 2005 and 2013.

• Sulfur dioxide (SO2) emissions decreased by 40% between 2005 and 2013.

• Employees’ recordable incident rate decreased by 9% between 2007 and 2013.

In addition to reporting on performance, the Sustainability Progress Report illustrates how the forest and paper industry is supporting a green economy through resource efficiency, carbon sequestration, innovative technologies, bio-based products, and benefiting communities. Contributing to the 2015 report are forest and paper industry associations from Australia, Brazil, Canada, Chile, China, Europe, Japan, New Zealand, South Africa, and the United States.

For more information about the sustainability of the global forest and paper industry, visit icfpa.org.

2030 Industry Manifesto

In 2011, as a leading industry Cepi published a 2050 Roadmap to a low-carbon bio-economy (here). Cepi is now releasing the 2030 Manifesto that takes into account the new adopted targets in the framework of the EU Green Deal.

“The Pulp and Paper sector is in a key position to support

the EU in becoming fit for 2050. Our sector has several

potentials to substantially and sustainably reduce greenhouse

gas emissions. In order to achieve these aspirations,

the availability of political support will be critical.”

21 March – International Day of Forests

European pulp and paper industry takes care of the forest

“The paper industry destroys forests”:a common misconception put forward by environmentalists all around the globe. What they don’t realise is that the European paper industry…

– contributes to keep up forests.

– practices sustainable forest management.

– is not responsible for the depletion of tropical forests.

From all the wood extracted around the world’s forests, 53% is used for energy production, 28% is used by sawmills and only around 11% is used directly by the paper industry(1). The paper industry depends on wood and needs thriving forests. It is very much in our interest that wood is used sustainably and will remain available as a raw material to future generations.

From a tree the branches cut to maintain a healthy forest are used for paper making. Residues from saw mills such as wood chips, are also used as raw material for paper. Over the years, thinning operations weed out the weaker trees, but there is still a net gain. The Food and Agriculture Organization (FAO) calculates that the annual increase of forest cover in EU 27 member countries is app. 503 000 ha/yr. This corresponds to the size of 3403 football (soccer) fields per day and an area almost twice as large as Luxembourg every year(2).

Deforestation is generally occurring in the southern hemisphere and is mainly due to unsustainable agricultural practices and fuel requirements. The European paper industry supports sustainable forest management as well as certification. A sustainable forest management strategy aimed at maintaining or increasing forest growth, while producing an annual sustained yield of wood, will generate the largest carbon storage benefit(3). We support certification as a way of documenting sustainable forest management. Certificates based on defined criteria issued by independent auditors make this verifiable for customers and consumers(4). Half of Europe’s forests and 92.2% of forests owned by paper companies are certified(5).

In Europe, the paper industry signed up for a Legal Logging Code of Conduct(6) in 2005 firmly condemning illegal logging and related corruption and criminal activities. Our commitment to responsible sourcing is clear and beyond any reasonable doubt.

More forest related news in the European paper industry at http://www.cepi.org/topics/forest

Or visit paperonline.org for more myth busters at http://www.paperonline.org/myths-and-realities

Information about the International Day of Forests: http://www.fao.org/forestry/international-day-of-forests/en/

1. FAO Statistics 2007

2. FAO Statistics 2010

3. 4th Assessment of the UN intergovernmental Panel on Climate Change (IPCC)

4. To learn more about certification, please visit www.fsc.org and www.pefc.org

5. CEPI Sustainability Report 2011

6. Legal Logging Code of Conduct for the Paper Industry

21TH CENTURY & BEYOND…

Paper is an amazing product: it is renewable, clean and incredibly versatile. It continuously offers new possibilities, applications and end-uses.

Paper can be impregnated, enamelled, crêped, waterproofed, waxed, glazed, sensitised, bent, folded, twisted, crumpled, cut, torn, dissolved, moulded and embossed. Who knows to what uses it will be put in the future?

Today, intelligent paper used in packaging allows us to see clearly if products are past their sell-by date by changing colour, printed electronic circuits can be used instead of traditional heavy circuit boards, scratch and sniff books bring learning to life, radio identification tags allow products to be traced at every stage, and even batteries can be made from paper.

What is sure is that the European pulp and paper industry will continue to change and adapt to new market conditions, responding to consumer requirements, and moving closer to its vision of integrated sustainability and competitiveness.

Paper mills have improved enormously from an environmental point of view (waste water, emissions, etc.) as well as from an efficiency point of view (see Environment section).

3.5 million jobs at risk if EU grants Market Economy Status to China, finds new report

A landmark study by the Economic Policy Institute (EPI) released last week reveals that if the EU grants Market Economy Status (MES) to China, the EU could lose 3.5 million jobs and 2% of GDP. Read AEGIS Europe press release here.

CEPI is a member of the AEGIS alliance. Follow AEGIS on Twitter @AEGISeurope

4evergreen launch event – Virginijus Sinkevičius, EU Commissioner for Environment

“This alliance is clearly in step with our thinking and with our objectives for a circular low-carbon future. A future where sustainability goes hand in hand with innovation and creates exciting business opportunities“

Welcome and video address by Virginijus Sinkevičius, EU Commissioner for Environment, at the official 4evergreen launch event on 25 Nov 2020. Watch the full message:

5th European Paper Recycling Awards call for candidates is open!

The European Recovered Paper Council (ERPC) launched a call for candidates for the 2015 European Paper Recycling Awards. The awards will identify projects, initiatives and campaigns that contribute to Europe’s sustainability through activities supporting paper recycling. Winners will be announced at the official awards ceremony taking place at the European Parliament on 14 October.

Now in their fifth edition, the awards are open to all entities based in Europe, including schools and universities, NGOs, national and regional authorities, companies and associations.

Read the press release here.

To apply, please visit the ERPC website at www.paperforrecycling.eu.

A Checklist for EU and Climate Policies

The document is available here.

A joint call for an updated and stronger EU Forest Strategy

Acknowledging the report from the European Commission on progress in the implementation of the Forest Strategy the undersigned organizations, representing forest owners, managers, contractors and the forest-based industry, call on the European Commission, Parliament and Council to update the EU Forest Strategy with an aim to strengthen its role as a key reference for sustainable forest management. An update of the EU Forest Strategy is essential to ensure that the development of forest-related EU policies in the coming decades is better coordinated and more coherent.

Since the EU Forest Strategy was adopted in 2013, the EU policy framework and the EU policies affecting forests have strongly evolved. It is now more broadly recognized that forests and the forest sector play a crucial role in addressing major challenges in line with the United Nation’s Sustainable Development Goals and the climate change mitigation goals of the Paris Agreement.

In this context, special care must be taken to recognize the role of Sustainable Forest Management (SFM) to ensure forest ecosystem’s health and vitality and the delivery of multiple advantages to society and the bioeconomy.

However, forests and the forest-based sector are now increasingly expected to deliver on horizontal and sectoral EU policies addressing forests. These include:

– The 2050 Climate Change Mitigation Strategy that aims to maximize the potential of carbon storage in forests while providing raw materials for renewable products used to substitute for non-renewable materials as well as for energy.

– The land use and forestry regulation for 2021-2030 which commits Member States, for the first time in EU law, to compensate land use and forestry sector emissions by CO2 removals within the sector.

– The European Commission proposal for a taxonomy of sustainable investments which recognizes the central importance of sustainable forest management for protecting ecosystems.

– The EU Renewable Energy Directive that sets out bioenergy sustainability criteria related to forest management and GHG emissions savings.

– The updated EU Bioeconomy Strategy that encourages the transition to a more bio-based circular economy, bringing new opportunities for jobs and growth to rural areas.

– The future CAP which is the main instrument at EU level to finance measures that support SFM and investments for enhancing the sustainability and competitiveness of the forestry sector.

– The EU Biodiversity Strategy which aims to halt the loss of biodiversity and ecosystem services in the EU and which the Commission has recently started to evaluate.

The consequences of these policies and strategies on forests and their sustainable management still need to be ascertained. Therefore, their implementation during the period 2020-2030 and beyond must be closely monitored from a forestry perspective. In this context, the EU Forest Strategy can and should provide a consistent basis on which to strengthen and further establish effective links between forests and the forest-based sector and any relevant EU policies.

Beyond consistency throughout its legislation and policies, the EU also needs an efficient tool to address forest and forest-related issues on the pan-European and international agendas. Member States and their pan-European partners in Forest Europe are determined to continue discussions on a legally binding agreement on forests. At global level, a well-prepared and coordinated input is needed to the UN Strategic Plan for Forests 2030 and the Global Forest Goals. A robust EU Forest Strategy is the appropriate instrument to ensure consistent input to these processes, thereby making the EU a strong and committed partner.

Over the last years the Strategy has undoubtedly played a positive role in this context.

However, more needs to be done both at EU and national level to ensure even better policy consistency and coherence in the future. The roles of the Standing Forestry Committee and also of the Civil Dialogue Group on Forestry and Cork are very important in this context.

While the progress report highlights the importance of continued implementation of the strategy, it refrains from concrete recommendations for the post-2020 period. Therefore the undersigned organizations call on the European Commission, Parliament and Council to propose an updated and stronger EU Forest Strategy, before the end of 2019, which encompasses recent and upcoming EU policies and is adequately resourced at the appropriate levels of the European institutions.

CEETTAR – European Organisation of Agricultural, Rural and Forestry Contractors

CEI-BOIS – European Confederation of the Woodworking Industries

CEPF – Confederation of European Forests Owners

CEPI – Confederation of European Paper Industries

COPA COGECA – European Farmers and European Agri-cooperatives

ELO – European Landowners’ Organization

EUSTAFOR – European State Forest Association

UEF – Union of European Foresters USSE – L’Union des Sylviculteurs du Sud de l’Europe

A long-term strategy for Europe’s industrial future: from words to action

The Joint Paper presents concrete industrial policy proposals in seven priority fields; business-friendly policy environment, sustainability at business core, upgraded skills and training, enhanced research and innovation, investment and improved access to finance, reinforcement of the European Single Market and strengthened trade and international market access.

The 149 industry organisations behind Industry4Europe stand united in their repeated calls for an ambitious and long-term EU industrial strategy that must help Europe remain a hub for a leading, smart, innovative and sustainable industry, that provides quality jobs and benefits all Europeans and future generations.